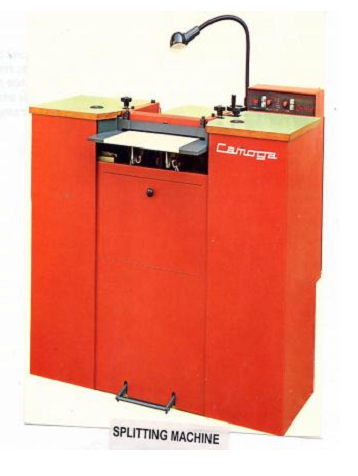

Splitting machine is one of the most important machines in leather goods manufacturing. Finished leathers available from tanneries will have more thickness than the requirement for making leather goods. Since leather goods are made with different thickness, it is necessary to split the leather components according to the required thickness. This can be achieved only with the help of a splitting machine.

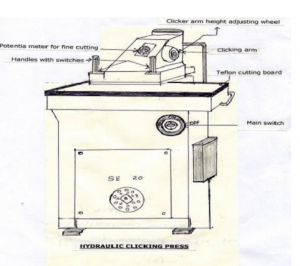

Parts of the splitting machine :

- On/off switch : The part on & off the machine.

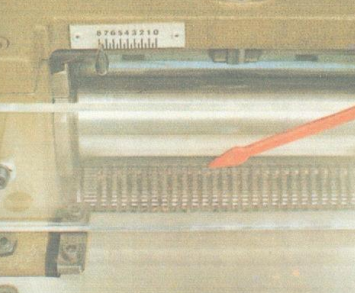

2. Top Feed Roller. This helps feed the leather through. It is smooth so as not to damage the leather grain surface. It is not spring-loaded.

Top feed roller height adjustment knob. When turned clockwise lowers the roller, anti-clockwise raises the roller. The height of the roller determines the end thickness of the leather after splitting.

Top feed roller supporting blocks

Top feed roller height adjusting wedges

Top feed roller adjusting shaft, When turned, pulls the wedges in or pushes them out.

Top feed assembly plate. This plate holds the top feed assembly in place.

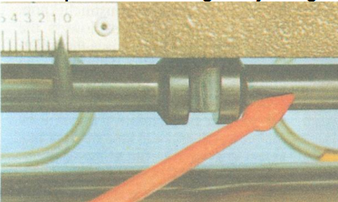

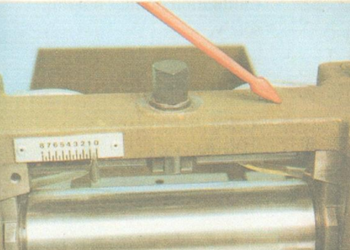

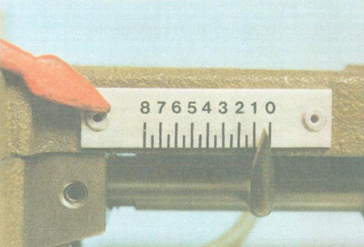

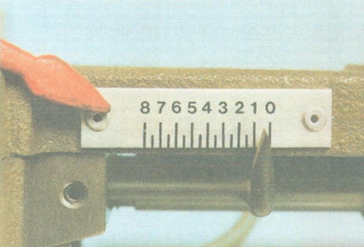

Calibration plate: This is marked off in millimeters & indicates the remaining substance of leather after splitting.

Calibration pointer: This is housed in the adjusting wedge.

Transparent safety sheet. This slides up or down to allow for different thicknesses of leather

Worktable

Front cover plate

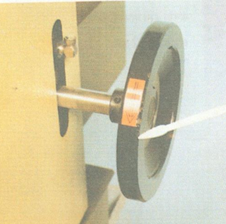

Handwheel. To manually turn the rollers and release jammed leather

Leather catching tray.

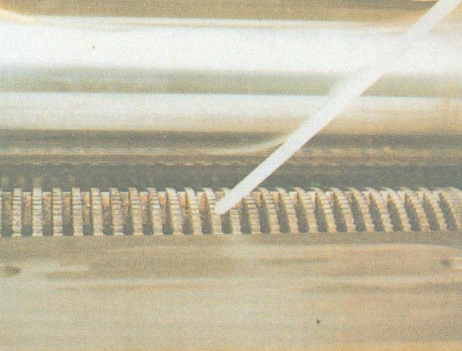

Bottom feed roller. This is a serrated roller with spacing between the serrated edges. It is spring loaded. They are slightly higher than the roller at the rear.

Anti-offal jamming lever:

- These are placed between the bottom feed roller spaces.

- They are slightly higher than the roller at the rear.

- They are spring-loaded.

- They prevent the offal from clinging to the bottom-feed roller, even the smallest piece.

Safety Measurement and problems and solutions:

a) Turn off the machine

b) Pull the handwheel towards yourself (Some- times the leather will feed on a manual movement as against power.

c) If this does not feed the leather

d) Raise the top roller

Do not fool around on the machine Only one person to operate the machine at a time

Do not try to do your 0wn electrical repairs.

Never lean across the top of the machine to pick up the leather.

Always remove jammed leather with a stick or brush.

Wearing safety apron when operates the machine. This apron safe your body. Wearing safety hand gloves in hand when operates the machine

Operations:

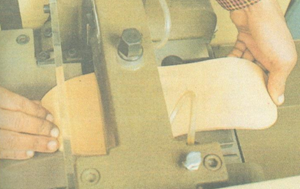

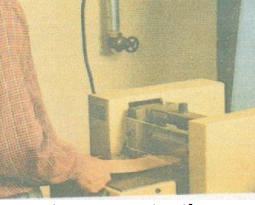

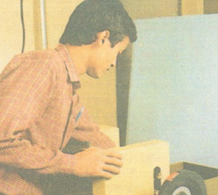

The machine is switched on and the position of the knife is checked through the viewfinders whether the knife is touching the splitting line. If not, the necessary adjustment is made to move the blade to coincide with the splitting line for uniform and accuracy of splitting. Before feeding the components for splitting, the blade is sharpened well by adjusting the grinding unit screws for uniform and perfect splitting. In the case of bulk production, the sharpening of the knife is continued until the splitting of the components is over. The speed rate switches are switched on according to the speed of the production.

The splitting thickness of the components is adjusted by the thickness adjusting wheel, which can be seen from the digital display. Since, each part of the product needs different splitting thickness, it is necessary to adjust the thickness while splitting the components. Upper guide roller is used to split to the thickness from 0.5mm to 12mm. In case, if the splitting thickness of 0.2mm is needed, the guide bar is used. The working width for splitting ranges from 300mm to 500mm. Since the upper guide roller rotates simultaneously along with lower feed roller, the leather components can be easily fed for splitting. The components for splitting are fed one by one. Random checks for uniformity splitting thickness can be done by using thickness measuring equipment. In certain components where partial splitting is required, the same is achieved by switching on the partial splitting switch and adjusting the partial splitting length adjusting knob. After splitting, the components of the products are inspected for the quality of splitting and then sent for the next unit operation.

Caution

i. The grinding stone must be dressed periodically for smooth sharpening of the knife.

ii. After the sharpening of the knife, the burr must be removed by the dressing tool for perfect skiving.

iii. Presser foot should not touch the feed roller while skiving, otherwise both presser foot and feed roller will get damaged.

iv. Feed roller must be at a suitable distance from the knife while skiving. If the feed roller is touching the knife, the feed roller will get damaged.

v. For taper skiving, both presser foot and the feed roller must be at the same angle. Otherwise, both presser foot and feed roller will get damaged.

vi. If the bell knife gets reduced and not fit for skiving, a new bell knife must be replaced.

Reference:

- MANUAL FOR LEATHER ACCESSORIES AND LEATHER GOODS ..SUBRAMANIAN NATESAN

- CFTC class note

- National Technical and Vocational Qualification Framework .. Notes

Please share your feedback and suggestions. In case if you have any queries about any topic of Footwear and Leather Goods, post it in the comment section. And if you like this topic you may share it on Facebook, Twitter or any social site. Thank you.